In today’s industrial landscape, the demand for high-quality, precision mechanical components is ever-increasing. Precision mechanical processing, also known as precision machining, involves the creation of intricate parts and components with tight tolerances. When scaled to large quantities, this process becomes a critical backbone of manufacturing industries, ensuring consistency, reliability, and efficiency. This article delves into…

In the field of international trade, handling export documents and records is crucial to ensure transactions run smoothly and comply with various regulations. The two main elements in this process are the Certificate of Origin (CO) and the Certificate of Quality (CQ). These documents play a vital role in verifying the origin and quality of…

In the precision manufacturing field, CNC processes are among the most reliable and efficient methods for producing complex parts with high accuracy. However, despite the advanced capabilities of CNC machines, backlash errors can still occur, posing challenges to achieving desired accuracy and quality of the final product. Identifying Backlash Errors in CNC Machining Backlash errors…

In the world of materials science and industrial manufacturing, innovation is key to achieving superior performance and durability. One such innovation is the combination of anodization with powder coating, a technique that merges two powerful processes to create highly resilient and efficient surfaces. This article explores the benefits, applications, and technical aspects of this hybrid…

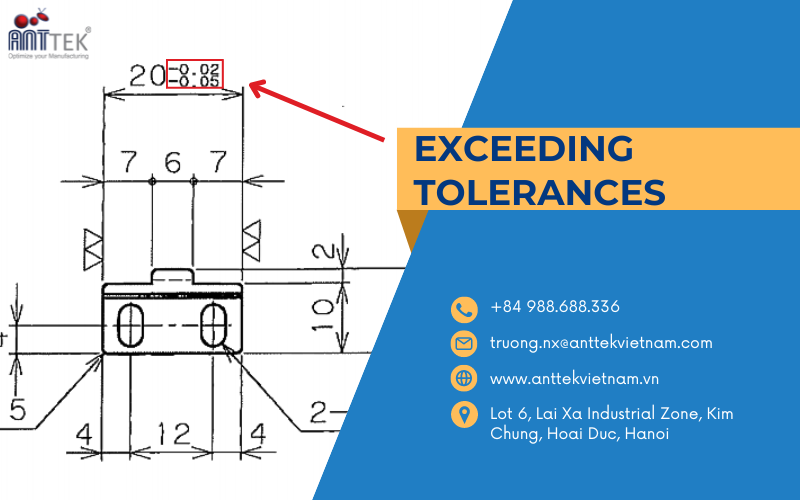

Precision mechanical processing is a technical process that demands high accuracy and finesse in every detail of the product. During this machining process, tolerance plays a crucial role in ensuring that the final product meets quality and precision requirements. However, exceeding allowable tolerances can lead to serious consequences for the product and overall production process. …

Salt bath nitriding is a surface-hardening process that significantly enhances the properties of precision mechanical components. By infusing nitrogen into the surface layer of ferrous materials, this technique improves hardness, wear resistance, and fatigue life. The method is particularly valuable in precision mechanical machining, where the performance and longevity of parts are crucial. What is…

Precision mechanical processing is a field where even the smallest deviations can lead to significant issues. One such issue is the NG (Not Good) series, a term used to describe parts that fail to meet the required specifications and tolerances. NG series parts are a critical concern in industries where precision is paramount, such as…

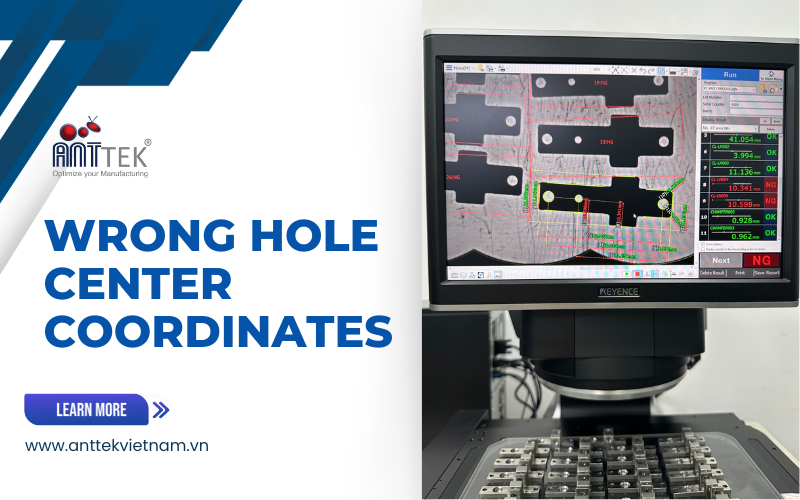

Precision is paramount in mechanical processing, where even minor discrepancies can lead to significant issues in the final product. One critical aspect of precision machining is ensuring the accurate placement of holes according to specified coordinates. When these coordinates are incorrect, it can result in a cascade of problems that affect the functionality, integrity, and…

Surface treatment plays a crucial role in enhancing the performance, durability, and aesthetic appeal of manufactured components across various industries. However, the process of surface treatment can also impact the dimensional tolerances of these components. Managing tolerances effectively post-surface treatment is essential to ensure that the final products meet the required specifications and maintain high…

Precision mechanical parts processing is a critical field within manufacturing, playing a pivotal role in producing components that demand high accuracy, reliability, and performance. This process involves the fabrication of intricate and complex parts used in various industries such as aerospace, automotive, medical, and electronics. The importance of precision in this context cannot be overstated,…