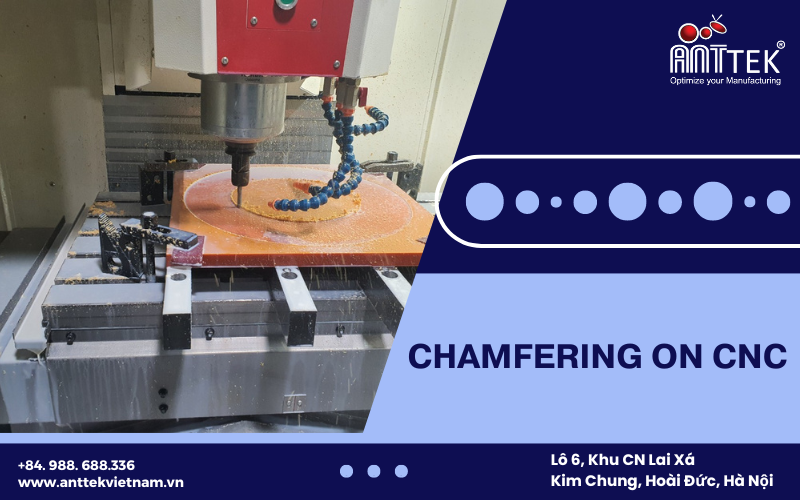

Chamfering, a process of beveling or rounding off the sharp edges of a workpiece, is a critical step in manufacturing across various industries. Whether you’re crafting intricate metal components or sculpting precise wooden structures, chamfering enhances both aesthetics and functionality. With the advent of CNC machining, chamfering has reached new heights of precision and efficiency. …

In modern manufacturing, the combination of CNC (Computer Numerical Control) machining and powder coating provides a powerful duo for creating high-quality, durable, and aesthetically pleasing metal parts. CNC machining allows for precise and efficient production of components, while powder coating offers superior surface finishing and protection. The Benefits of Powder Coating Powder coating is a…

Tapping is commonly used in a wide range of industries, including manufacturing, automotive, aerospace, and construction, wherever threaded connections are needed. It is a fundamental process in the production of components and assemblies, contributing to the functionality, reliability, and integrity of various mechanical systems. What is Tapping? Tapping is a fundamental process in manufacturing, essential…

The check pin, a crucial component in mechanical assemblies, serves to ensure alignment, stability, and functionality. When a hole intended for a check pin becomes tighter than expected during machining, it can disrupt the entire manufacturing process, leading to delays and potential rework. Understanding the causes and remedies for this issue is crucial for efficient…

CNC machines have revolutionized the precision and efficiency with which we can produce complex components. Welding, a critical process in fabricating durable and high-strength joints, has also seen significant advancements. Among the most prominent welding techniques used in conjunction with CNC technology are Tungsten Inert Gas (TIG) welding and laser welding. Both methods offer unique…

In the realm of CNC machining, precision is paramount. Each cut, each groove, and each texture must be meticulously crafted to exact specifications. Among the myriad techniques employed in CNC machining, knurling stands out as a method for adding texture and grip to cylindrical surfaces. Let’s delve into what knurling is, its applications, and how…

Electrical Discharge Machining (EDM) is a non-traditional machining process widely used in various industries to produce complex shapes and precision parts. Despite its advantages, EDM can sometimes produce parts with size deficits, where the final machined part is smaller than the intended size. Understanding the causes and solutions for size deficit in EDM is crucial…

Precision mechanical processing demands the highest levels of accuracy and consistency to ensure the production of high-quality parts and components. Central to achieving these standards is the rigorous quality control (QC) process, which relies heavily on specialized measuring tools like pin gauges. In this article, we delve into the indispensable role of pin gauges…

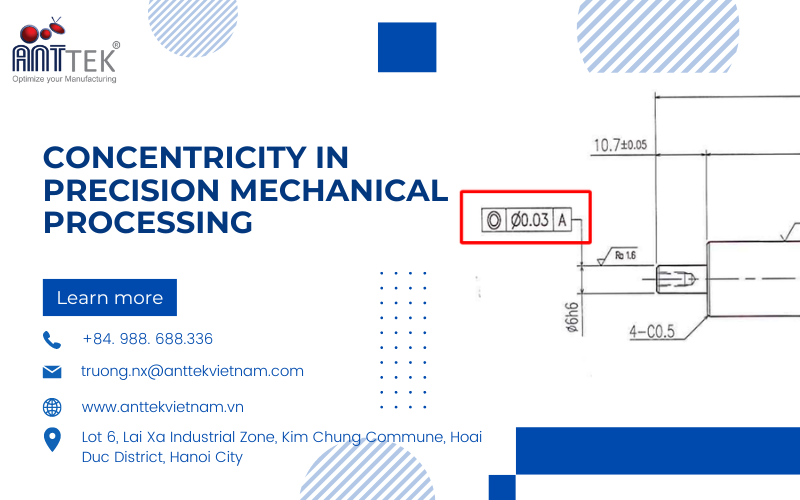

Precision mechanical processing is a critical aspect of manufacturing, particularly in industries that demand high levels of accuracy and reliability. One of the essential parameters that engineers and manufacturers focus on is concentricity. Concentricity plays a pivotal role in ensuring the functionality, performance, and longevity of mechanical components and assemblies. What is Concentricity? Concentricity refers…

In the realm of precision mechanical machining, where every micron counts, the smallest details can make a significant difference in the quality and functionality of the final product. One such crucial detail is chamfering, a process that not only enhances the aesthetics of a component but also plays a vital role in functionality, particularly in…