Powder coating is a popular surface treatment method in the mechanical industry, providing protection against corrosion, impact, and other environmental factors. To ensure the quality and effectiveness of the coating, adherence to powder coating standards is critical. Below are the key standards that mechanical components must meet when using powder coating. Surface Preparation Standards To…

I. Overview of PU plastic and the common applications of bonding PU plastic to metal 1.1 What is PU Plastics? Polyurethane (PU) plastic is a type of polymer known for creating durable and robust coatings. Widely used in various industries, PU plastic offers outstanding features such as wear resistance, chemical resistance, and excellent elasticity. Bonding…

I.Tổng quan về nhựa PU và ứng dụng của dán nhựa PU lên kim loại 1.1. Nhựa PU là gì? Nhựa PU (Polyurethane) là một loại polymer có khả năng tạo ra lớp phủ chắc chắn và bền bỉ. Được sử dụng rộng rãi trong nhiều ngành công nghiệp, nhựa PU cung cấp các tính…

Machining is a crucial process in mechanical engineering that ensures the accuracy in dimensions, shape, and surface quality of machine components. After casting, machining processes are performed. The choice of the right machining method not only enhances surface quality but also improves economic efficiency and reduces labor efforts. 1. What is metal machining? Metal machining…

Surface treatment for steel is an important process in steel production and processing, helping to improve material properties such as durability, hardness, corrosion resistance, and aesthetics. Types of Surface Treatment for Steel Galvanizing – Hot-Dip Galvanizing: This is the most common galvanizing method. Steel is dipped into a bath of molten zinc at about 450°C….

Nickel plating is an important technique in the metal surface treatment industry. This process not only enhances the aesthetic appearance but also improves the durability of metal products. What are the benefits of nickel plating? Increased Product Durability Nickel plating creates a protective layer on the metal surface, preventing direct exposure to environmental factors such…

The machining of composite structural components is becoming increasingly important and prevalent in the manufacturing industry. This is especially true as the demand for complex, precise, and high-performance products continues to rise. Composite structural machining is the process of using multiple machining methods to create a complete product, leveraging the advantages of each machining technique…

Machining machine parts is a crucial process in the mechanical engineering industry, where machine components are manufactured from raw materials into finished products with high precision. This process plays a key role in creating the essential parts and equipment needed for various sectors such as automotive, aerospace, and electronics. Methods of Machining Machine Parts There…

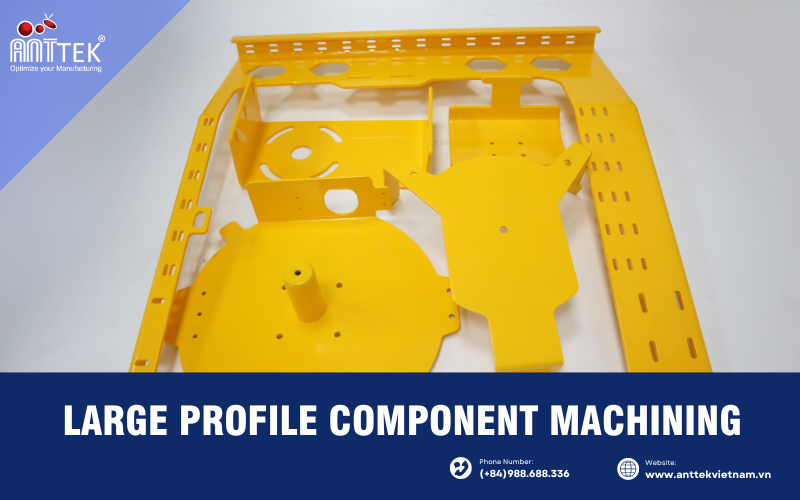

Machining of large profile components in precision mechanical engineering is a highly specialized field that requires a combination of advanced technology, sophisticated techniques, and stringent quality control processes. These components often have sizes significantly larger than conventional ones and are used in crucial applications such as aerospace, automotive, and industrial machinery. Characteristics of Large Profile…

In the realm of manufacturing, innovation is a constant pursuit, driven by the need for efficiency, precision, and cost-effectiveness. One such innovation that has been making waves in recent years is CNC combined casting processing. This groundbreaking approach combines the versatility of Computer Numerical Control (CNC) machining with the strength and flexibility of casting,…