Machining – The Optimal Solution for Precision Manufacturing

Machining is a crucial process in mechanical engineering that ensures the accuracy in dimensions, shape, and surface quality of machine components. After casting, machining processes are performed. The choice of the right machining method not only enhances surface quality but also improves economic efficiency and reduces labor efforts.

1. What is metal machining?

Metal machining is a method that uses cutting tools to shape, cut, and trim products from metal workpieces. This process typically involves the use of machines such as lathes, milling machines, drills, saws, and grinders to separate and shape metal sheets to the desired dimensions and forms.

2. Steps in metal machining process:

- Machining Planning: Define product specifications, choose appropriate materials, and determine the suitable machining method.

- Tool and Machine Preparation: Select the appropriate cutting tools and prepare machines like milling machines, lathes, etc.

- Surface Cleaning: Ensure the workpiece surface is free from dust or contaminants.

- Programming Setup: For CNC machines, programming of the necessary parameters is required.

- Metal Cutting: Perform the cutting operation based on the design.

- Inspection and Evaluation: Measure dimensions and check the accuracy of the machined parts.

- Finishing: Conduct surface finishing, painting, or other necessary post-processing steps.

3. Common machining methods

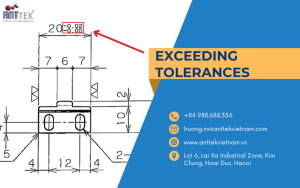

Turning: A machining process where the workpiece rotates and the cutting tool is stationary, removing material to achieve the desired shape. Turning can achieve high precision, with tolerances in the micrometer range.

-

- Types: CNC turning (computer-controlled) and manual turning.

- Milling: A machining process where the workpiece is fixed, and the cutting tool rotates to remove material. This method is effective for creating flat surfaces, grooves, or complex geometries.

- Performed on CNC milling machines or conventional milling machines.

- Drilling: The process of using a drill bit to create holes in the workpiece, typically for fasteners or assembly purposes.

- Grinding: A finishing process using abrasive wheels to achieve high surface quality and precision. Grinding is often used for parts requiring smooth surfaces and tight tolerances.

- Threading (Tapping): A process using a tap to cut internal threads or other detailed features on the workpiece by rotating the tool. This method is commonly used for creating threaded holes or precision parts.

4. Applications in Industries:

- Machine Manufacturing: Metal cutting is used to produce precision machine parts such as shafts, gears, and other critical components. High accuracy and durability are essential.

- Automotive: Components like crankshafts, pistons, and engine parts are machined through metal cutting to ensure performance and reliability.

- Electronics: The production of electronic components such as circuit boards, enclosures, and small precision parts benefits from metal cutting to achieve strict quality standards.

- Other Sectors: The aerospace, construction, and medical device industries also widely apply metal cutting techniques.

In conclusion, metal cutting is a vital manufacturing process in various industrial sectors. By utilizing advanced tools and techniques, engineers and manufacturers can produce metal components with high precision, meeting strict technical specifications. Effectively applying these techniques requires technical expertise, along with attention to factors like cutting speed, force, and temperature. When done correctly, metal cutting not only ensures product quality but also helps reduce production costs.

Anttek Vietnam – Diverse Metal Cutting Services

Anttek Vietnam takes pride in being a leader in metal cutting services with extensive experience in exporting to demanding markets such as Japan, the U.S., and Australia. We provide a wide range of metal cutting services to meet the needs of clients across different industries. With state-of-the-art equipment and a skilled technical team, Anttek Vietnam ensures high-quality products, timely delivery, and competitive pricing. We are always ready to support and collaborate with our clients for sustainable growth.

For more information, please contact:

- Factory: Lot 6, Lai Xa Industrial Zone, Kim Chung Commune, Hoai Duc District, Hanoi, Vietnam

- Hotline: +84 988.116.229

- Email: truong.nx@anttekvietnam.com

- Website: https://anttekvietnam.vn