Automated Goods Loading and Unloading System – The Optimal Solution for Manufacturing Plants

In the ever-evolving landscape of warehouses and distribution centers, Automated Goods Loading and Unloading Lines are transforming the way goods are handled. This innovative technology brings a plethora of advantages, including heightened productivity, reduced labor costs, and overall enhanced efficiency. Let’s delve into the outstanding features that make these systems a game-changer in the realm of logistics.

Outstanding Advantages of Automated Goods Loading and Unloading Lines

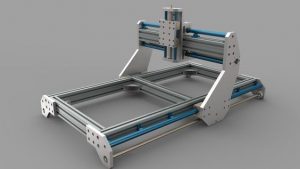

Photo 1: Roller Flow Rack with Conveyable Work Tables – Anttek Vietnam specializes in consulting solutions and designs according to customer requirements

Enhanced Efficiency

At the core of these automated cargo handling lines is the ability to revolutionize traditional manual processes. By integrating advanced robotics and sophisticated sensor technology, these systems execute cargo loading and unloading tasks with remarkable speed and precision. This not only accelerates overall workflow but also minimizes the risk of errors associated with human intervention.

Optimize Space Usage

In warehouses where space is a premium, automated goods handling systems prove invaluable. Specifically designed to maximize vertical space utilization, these systems enable higher stacking of goods, thereby optimizing storage capacity. This becomes particularly advantageous in high-cost environments.

Reduce Labor Costs

A significant advantage of automatic loading and unloading lines is the substantial reduction in labor costs. Through the automation of repetitive and physically demanding tasks, businesses can cut back on expenses related to manual labor, including wages, benefits, and training costs.

Enhanced Safety

Prioritizing safety, automated systems incorporate integrated sensors and algorithms to ensure precise handling of goods, reducing the likelihood of damage and creating a safer working environment for warehouse employees.

Operates 24/7

Unlike human workers with prescribed shifts, automatic loading and unloading lines operate seamlessly around the clock. This continuous operation capability enables businesses to meet the demands of a 24/7 economy, minimizing downtime and improving responsiveness to customer needs.

Automatic Goods Loading and Unloading Line in Mechanical Processing

The application of automatic loading and unloading lines extends into the realm of mechanical processing, offering efficiency, cost reduction, and enhanced production productivity. Key components and features associated with such systems include:

Conveyor System

A fundamental part of the automatic loading and unloading line, conveyor systems transport raw materials or workpieces between different processing stations.

Photo 2: Conveyor system and operating table combined with conveyor belt of Anttek Vietnam

Robotic Arm or Automated Guided Vehicle (AGV)

Robotic arms or AGVs handle loading and unloading tasks with precision, executing programmed movements for optimal material placement.

Material Handling System

Automated material handling systems, such as palletizers and robotic pickers, manipulate raw materials or finished products, providing flexibility in manufacturing processes.

Loading/Unloading Station

Dedicated stations with fixtures or clamps secure workpieces during processing at different stages of the production line.

Control System and PLC

A central control system, typically based on a Programmable Logic Controller (PLC), orchestrates the overall operation, ensuring a smooth and synchronized workflow.

Anttek Vietnam – Specializing in Automated Cargo Loading and Unloading Chain Solutions

Anttek Vietnam takes pride in offering high-quality, reliable solutions for automated goods loading and unloading lines. With years of experience in design and customized solutions,

Anttek Vietnam has become a trusted partner for both domestic and international customers.

Contact Details:

- Address: Lot G07, Kien Hung Land QSD Auction, Kien Hung Ward, Ha Dong District, Ha Noi City, Vietnam

- Factory: Lot 6, Lai Xa Industrial Zone, Kim Chung Commune, Hoai Duc District, Hanoi City – Vietnam

- Hotline: 0968.116.229 – 086.998.2628

- Email: khoi.pd@anttekvietnam.com

- Website: https://anttekvietnam.vn