POM Plastic Machining: Essential Factors for Achieving Precision and Dimensional Stability with Anttek Vietnam

POM is an ideal material for manufacturing precision mechanical parts in various industries.

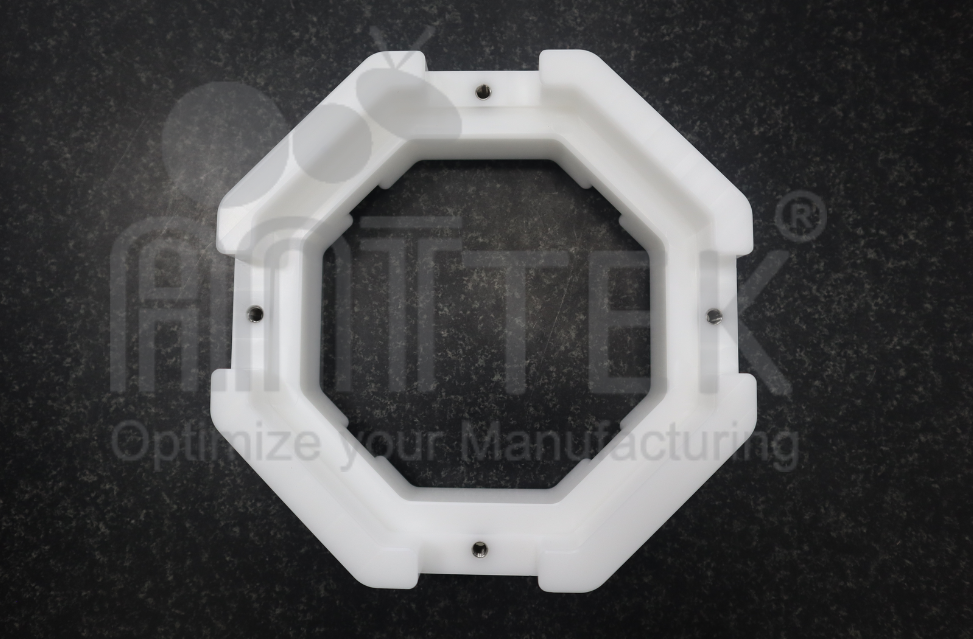

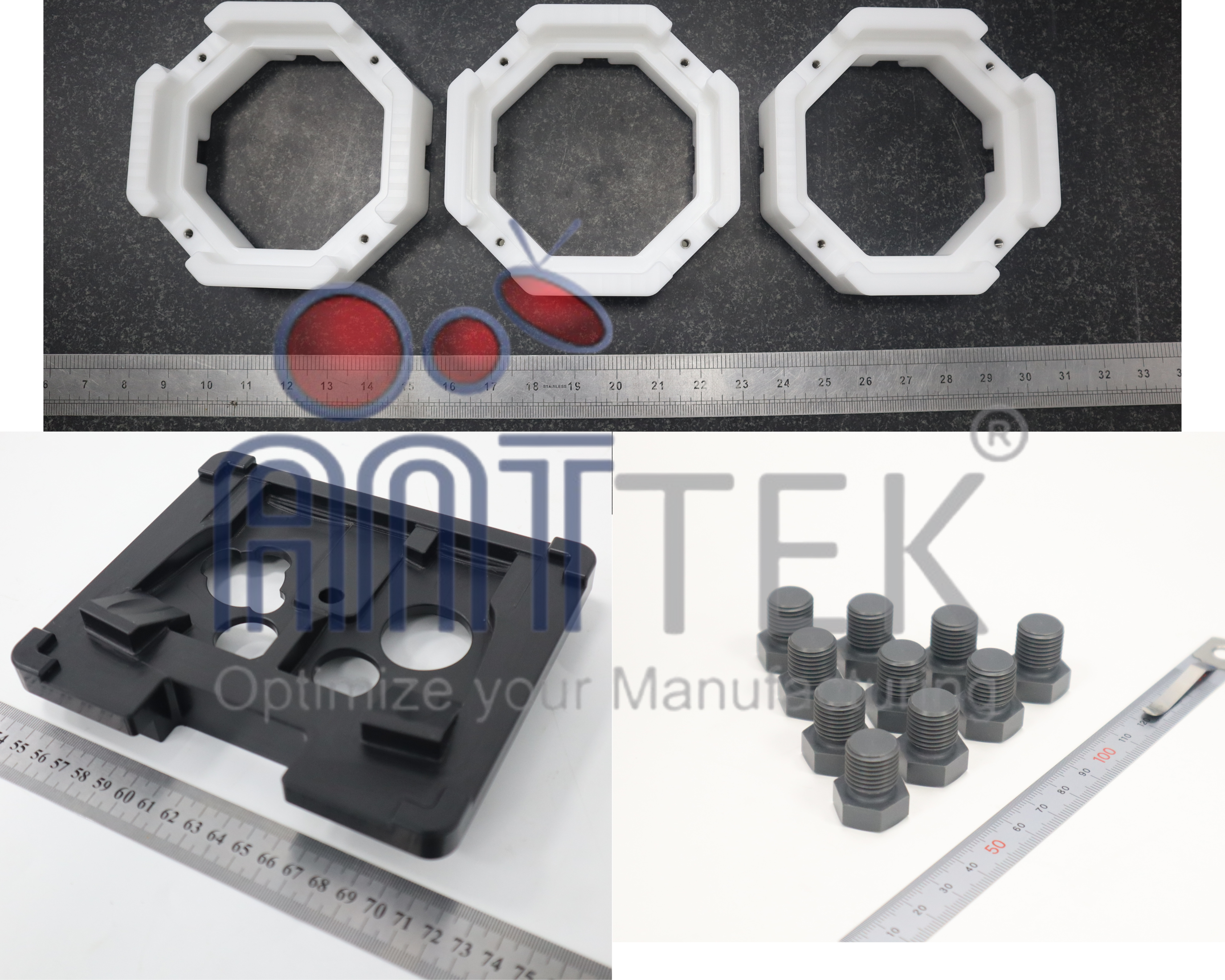

At ANTTEK Vietnam, we machine POM plastic for applications in mold making, jigs & fixtures, EV battery components, and EV batteryequipment.

1. What is POM Plastic?

POM (Polyoxymethylene) is a high-performance engineering thermoplastic with excellent tensile strength, rigidity, and wear resistance.

It offers outstanding dimensional stability and heat resistance, ensuring high machining accuracy and a smooth surface finish.

Common applications of POM in mechanical machining include:

-

Gears, shafts, and guide pins

-

Jigs, fixtures, and mold components

-

Drive parts and motion mechanisms in robots and industrial machines

-

Precision plastic components in EV batteries, semiconductors, and measuring devices

2. Outstanding Properties of POM

POM exhibits superior mechanical and physical properties for CNC machining, including:

2.1. High strength and rigidity

POM withstands heavy loads and maintains rigidity under continuous operation.

→ Suitable for load-bearing parts such as gears, cams, guide bushings, and sliding joints.

2.2. Excellent dimensional stability

With a low thermal expansion coefficient and minimal moisture absorption, POM retains its geometry even under changing temperatures and humidity.

→ Ideal for components requiring tight tolerances or precise assembly.

2.3. Smooth surface and low friction coefficient

POM’s friction coefficient (0.2–0.35) ensures smooth motion without lubrication.

→ Perfect for moving components, sliding rails, and low-friction mechanisms.

2.4. Chemical and industrial resistance

POM resists oils, greases, organic solvents, and light chemicals, maintaining integrity in harsh industrial environments.

→ Ensures long-term durability in factories, clean rooms, and automated systems.

2.5. Heat resistance and insulation

POM can withstand continuous temperatures up to 100–120°C without deformation and has excellent electrical insulation properties — widely used in industrial electrical and electronic devices.

2.6. Easy to machine and shape

POM offers excellent machinability for CNC milling, turning, drilling, tapping, wire cutting, and fine grinding.

→ Achieves smooth surfaces, tight tolerances, and reduced finishing time and cost.

3. Important Notes When Machining POM

Although relatively easy to machine, achieving optimal precision and durability requires understanding POM’s material characteristics and adjusting machining conditions properly.

3.1. Cutting temperature and speed

POM melts at around 165–175°C.

Excessive temperature can cause burning, decomposition, or discoloration.

→ Solutions:

-

Maintain moderate cutting speed and feed rate.

-

Use sharp tools with large chip clearance.

-

Apply coolant or compressed air to control temperature.

3.2. Clamping pressure and elastic deformation

Due to its elasticity, excessive clamping can cause temporary deformation.

→ Solutions:

-

Use light clamping force or vacuum suction for thin parts.

-

Perform multiple light finishing passes to minimize dimensional error.

3.3. Burr removal and surface finishing

POM’s softness can easily cause burrs along cutting edges.

→ Solutions:

-

Use ultra-sharp tools and high-speed, low-feed finishing passes.

-

Remove burrs using heat blades, hot air, or fine sanding.

3.4. Dimensional stability after machining

Machined POM parts may shrink slightly due to internal stress.

→ Solutions:

-

Allow parts to rest 12–24 hours before inspection or assembly.

-

Perform annealing at 80–100°C for tight-tolerance components.

3.5. Drilling, tapping, and threading

POM tends to deform and “flow” slightly when drilled or tapped.

→ Solutions:

-

Use plastic-specific drill bits with low helix angles.

-

Apply light lubrication and reduce spindle speed when threading.

-

Use metal inserts for durable threads if required.

3.6. Tolerance control and precision measurement

Because POM has a higher thermal expansion than metals, measurements can vary with temperature.

→ Solutions:

-

Measure in a controlled 20°C environment.

-

Use 3D CMM, 2D automatic measuring machines, and height/flatness gauges for comprehensive quality control.

4. ANTTEK VIETNAM – LEADING EXPERT IN POM CNC MACHINING

With over 8 years of experience in precision mechanical machining, Anttek Vietnam is part of the EV battery and semiconductor supply chains, meeting stringent requirements from demanding markets such as Japan, the U.S., and Korea.

We specialize in CNC machining of POM plastic in a variety of sizes, colors, and profiles — from single prototypes to mass production.

Machinery capability:

-

14 CNC milling machines (accuracy ±0.008 mm)

-

9 modern CNC lathes

-

Wire-cutting, surface grinding, and conventional milling systems

→ Capable of machining complex precision plastic and mechanical components.

Quality assurance and certification:

-

Equipped with 3D CMM, 2D automatic measurement, height, and flatness gauges.

-

Experienced QC team ensuring zero-defect (0NG) before delivery.

-

Full CO, CQ, and Mill Sheet provided; compliant with ISO and RoHS standards.

Flexible delivery:

-

Incoterms: EXW, FOB, CIF, DDU, DDP

-

Logistics partners: DHL, FedEx, Sagawa, OCS, and more.

5. International Experience and Partnerships

Anttek Vietnam has successfully delivered POM machining projects for major Japanese corporations such as:

Honda, Toshiba, Mazda, and Panasonic, in fields including:

-

EV battery components

-

Semiconductor parts

-

Precision industrial equipment

-

Molds and assembly jigs

6. Advantages of Working with Anttek Vietnam

-

High-precision machining, stable quality, and on-time delivery

-

Cost, time, and productivity optimization for every project

-

Technical support and co-development with customers

-

Multi-industry capability: molds, automotive, aerospace, energy, automation

-

Commitment to delivering real value and sustainable partnership

7. Conclusion

POM machining requires deep understanding of material behavior and precision manufacturing technology.

With advanced machinery, skilled engineers, and strict quality control processes, Anttek Vietnam provides comprehensive, accurate, and reliable CNC POM machining solutions.

👉 Let Anttek Vietnam accompany your business in creating value, elevating Vietnamese manufacturing, and reaching global markets.