Good surface with liquid nitriding heat treatment in precision mechanical machining

In the realm of surface engineering and material science, liquid nitriding stands out as a highly effective and specialized process for enhancing the surface properties of metallic components. This thermal diffusion treatment, often employed in the aerospace, automotive, and tooling industries, imparts superior hardness, wear resistance, and corrosion protection to metals. This article explores the intricacies of liquid nitriding, its benefits, and its diverse applications across various industrial sectors.

What is Liquid Nitriding?

Liquid nitriding, also known as nitrocarburizing or liquid carburizing, is a case-hardening process that involves the diffusion of nitrogen and carbon into the surface of ferrous materials, typically steel. The treatment is carried out in a liquid bath at elevated temperatures, usually around 500 to 580 degrees Celsius (932 to 1076 degrees Fahrenheit).

The liquid medium consists of ammonia and other nitrogen-rich compounds, creating an environment conducive to nitrogen absorption by the metal surface.

Process Steps

- Preparation: The metal components are thoroughly cleaned to remove contaminants, ensuring optimal results during the nitriding process.

- Heating: The parts are then heated in a controlled atmosphere to the desired nitriding temperature, typically within a range suitable for the specific steel alloy.

- Nitriding Bath: The heated components are immersed in a liquid nitriding bath containing ammonia or nitrogen-rich compounds. The chemical reactions between the steel surface and the nitrogen result in the diffusion of nitrogen and carbon into the material.

- Cooling and Post-Treatment: After the desired diffusion depth is achieved, the components are cooled and undergo post-treatment processes to enhance their final properties. This may include quenching, tempering, or other heat-treating steps.

Change in appearance of the metal surface when liquid nitriding heat treatment

When a metal surface comes into contact with and absorbs liquid nitrogen, several changes in its appearance and properties can occur. Here are some effects associated with the absorption of liquid nitrogen:

Color Change

The metal surface may undergo a temporary color change. This change is often due to the formation of a thin layer of frost or ice, and it can vary depending on the type of metal.

Frost Formation

The rapid cooling of the metal by liquid nitrogen can cause moisture in the air to condense and freeze on the surface, forming a layer of frost. This frost layer may appear white or opaque.

Brittleness

The extremely cold temperatures of liquid nitrogen can induce temporary brittleness in some metals. This may affect the surface’s mechanical properties, making it more susceptible to cracking or fracturing.

Thermal Contraction

The metal contracts as it absorbs the intense cold of liquid nitrogen, potentially leading to changes in the overall shape or dimensions of the material.

Black liquid nitrogen on the surface of the material

Nitriding typically doesn’t cause a black color change on the material’s surface. However, if there is an observation of a black appearance, it could be due to specific process conditions, variations in material composition, or post-nitriding treatments. For example, often referred to as “black oxide” or “blackening,” can be applied after nitriding to achieve a dark or blackened surface layer. This additional treatment serves several purposes, including corrosion resistance, aesthetic improvement, and sometimes, increased lubricity.

The black oxide coating is a result of a controlled chemical reaction that forms a layer of magnetite (Fe3O4) on the surface of the metal. This layer not only provides a black appearance but also enhances the material’s resistance to corrosion. It’s commonly used on ferrous metals, such as steel, to improve both functionality and aesthetics.

So, in the context of nitriding followed by a black oxide treatment, observing a black appearance on the material is a valid and expected outcome. This combination of processes provides a dual benefit of improved surface hardness and wear resistance from nitriding, coupled with corrosion resistance and blackened appearance from the subsequent oxidation process.

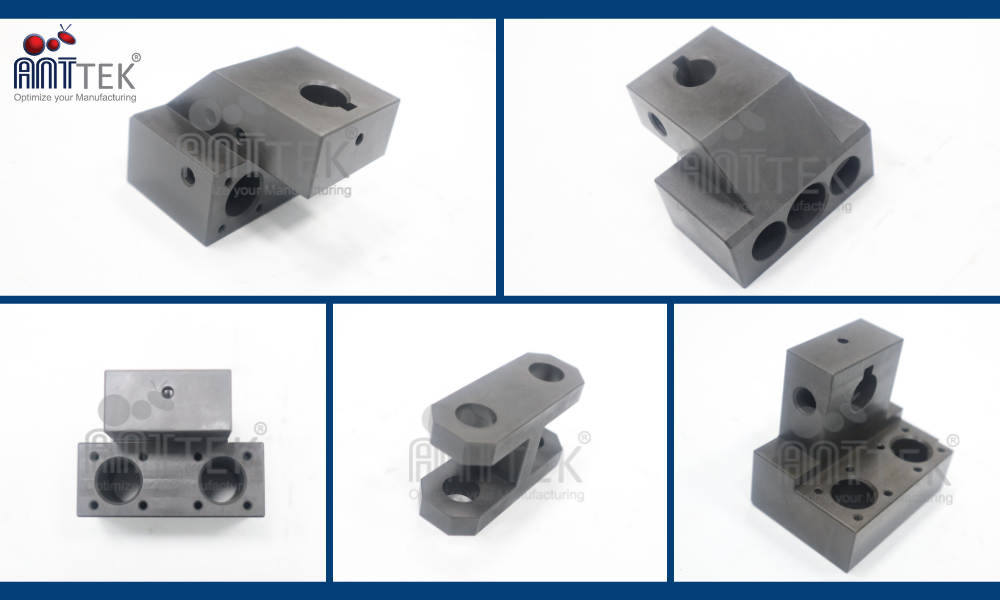

Image 1: Liquid nitriding surface treatment products of Anttek Vietnam

Advantages of liquid nitriding

Liquid nitriding, also known as nitrocarburizing, is a surface treatment process that offers several advantages, enhancing the properties of metal components. Below are some key benefits associated with liquid nitriding:

- Improved Hardness: Enhanced Surface Hardness: Liquid nitriding results in a hardened surface layer, contributing to improved wear resistance and extended service life of components. The process promotes the formation of hard nitride compounds, such as iron nitride, which significantly increases the surface hardness.

- Wear Resistance: Increased Wear Resistance: The hard nitride layer formed during liquid nitriding provides effective protection against abrasive wear, making treated components suitable for applications with high levels of friction, sliding, or abrasive contact.

- Corrosion Resistance: Enhanced Corrosion Resistance: Liquid nitriding improves the corrosion resistance of the treated components. The nitrided layer acts as a barrier against corrosive elements, making the material more resilient to environmental exposure.

- Dimensional Stability: Minimal Distortion: Liquid nitriding is known for inducing minimal distortion in treated components. This is especially crucial for precision parts and components with tight dimensional tolerances, as it ensures that the original geometry is maintained

Liquid nitriding stands out as a versatile and proven surface treatment method, offering numerous advantages that significantly enhance the longevity, durability, and performance of treated metal components. In response to the ongoing demand for materials with superior properties, liquid nitriding applications continue to play a pivotal role in achieving enhanced surface properties across various manufacturing sectors